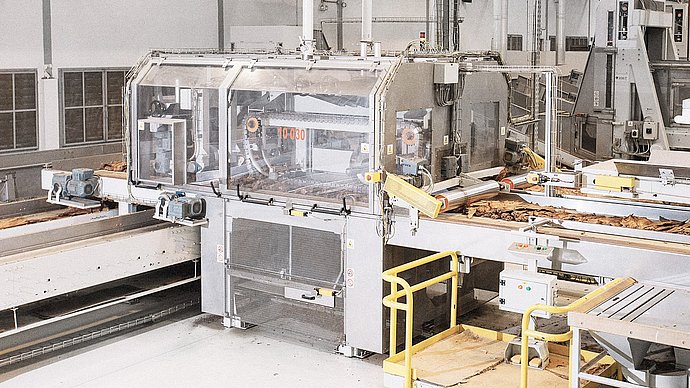

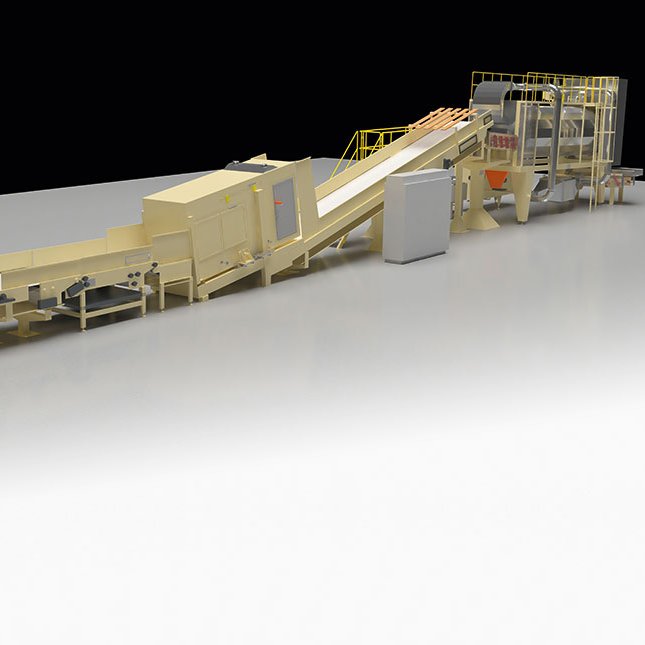

Unpacking

The tobacco leaves are delivered to the cigarette factories in 200 kg cartons or bales. There, unpacking stations unpack up to 48 cartons an hour, which is up to 12,000 kg of tobacco. The equipment can be converted to handle different types of carton in a few simple steps.

Slicing

A slicer cuts the leaves, which have been tightly compressed in cartons or bales for two years, into smaller slices. This prepares them for the next step of the process: conditioning and casing.

Conditioning and casing

The leaves are loosened and moistened with water and steam. As a result, the moisture content increases from 10 to 21 percent and the pores of the leaves open. This is followed by the “casing” process, in which the tobacco is sprayed with casing, a sugary liquid that can contain glycerin or flavors such as liquorice, chocolate or plum. These flavors penetrate into the leaf’s interior through the pores.

Storing and blending

Careful blending of the tobacco produces homogeneous and consistent blends. This process is crucial to ensuring the quality of a cigarette. The blending plants are not just used to blend the tobacco, they can also be used for other purposes, such as storage silos or buffers, for example.

Removal

Even the tiniest particles of non-tobacco material can adversely affect the appearance and taste of the final product. A number of systems are used to detect and remove these particles. These include magnets, conveyor belts with screens, separators, metal detectors and sophisticated optical detection systems.

Cutting

After blending, the leaves are cut. The blades on the tobacco cutters must be extremely sharp and clean to ensure a high-quality final blend, so they are sharpened automatically on a regular basis. Our tobacco cutters can process up to twelve tons of fine-cut tobacco and three tons of stems an hour.

Spares for tobacco cutters

We provide OEM spare parts for depreciated machines of our old brands Garbuio, Quester, Dickinson, Legg, AMF, and NTM. Benefit from our experience and service to keep your tobacco cutters running efficiently and for a long time.

Discover suitable machines

Expansion

The tobacco is heated very rapidly to over 100 degrees. Steam condenses during this process. This accelerates the heating process and causes the water in the cells to expand. As a result, the tobacco expands and its filling power increases. At the same time, its moisture content increases from 21 percent to approx. 25 percent.

Expansion and drying

First, the tobacco is heated very rapidly in combined expansion and drying plants. The water expands into the cells of the tobacco and increases its filling power. The moisture content increases from 21 to 25 percent. The tobacco is then dried just as rapidly in a flow of superheated steam. Its moisture content drops to 13 percent as a result. However, the cells remain expanded.

Drying

The tobacco is dried in a flow of superheated steam with a temperature of up to 300 degrees and a low oxygen content. This causes the tobacco’s moisture content to drop from 25 to 13 percent. The process is extremely gentle, thereby ensuring that the cell expansion previously achieved is maintained.

Cooling & separation

After drying, the tobacco is cooled. This stabilizes the additional filling power achieved and prevents the dried tobacco from losing any of its aroma before it enters the flavoring cylinder. Larger particles such as stems are also removed in the cooling plants.

Flavoring

In the last tobacco preparation step, flavors are sprayed evenly onto the cut tobacco, during which the tobacco is gently blended. This gives it its characteristic taste which ensures that distinctive smell when the cigarette pack is opened.

Rollers

The stems of the tobacco leaf are rolled flat, which widens them so that they can be processed more easily. The stems are low in nicotine and sugar. For this reason, they are often used to produce light, low-nicotine cigarettes.

Filling crates

Filling stations enable cigarette production to be scheduled with maximum flexibility. Here, cut tobacco is gently filled into containers or cartons, from which it can be removed as required during production. Among other things, the stations are equipped with mobile tippers or gantry robots as well as a storage area and fully automatic logistics equipment.

Feeding

Several tobacco feed plants are connected directly to the Secondary. They ensure that the cigarette makers receive a continuous supply of tobacco. They do so by transferring the tobacco via air pressure through long pipelines to the makers. The transfer capacity and air speed can be adjusted and controlled fully automatically.

Dust extraction

At all stations of the Primary, extractors and dust extraction systems clean the air of any tobacco dust whirled up during tobacco processing. Air-flow dust filters remove dust, and cyclones remove solid particles from the air. Both are collected and, if necessary, re-used.