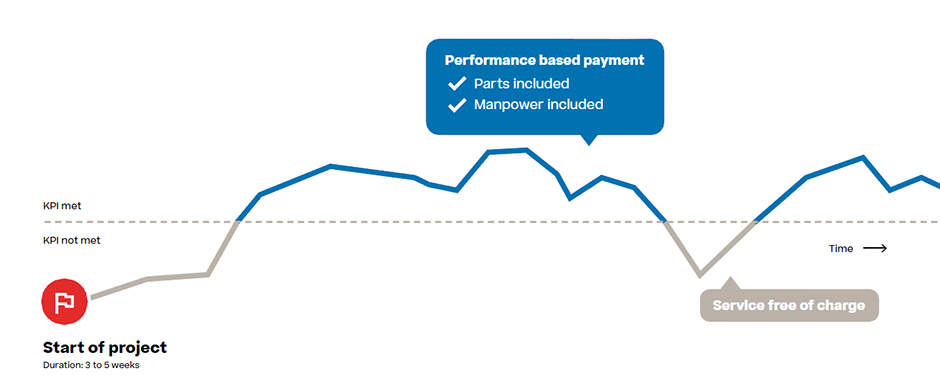

“Our innovative KPIdM approach is as simple as can be,” affirms Marco Castro, Global Head Advanced Services Körber Technologies. “Our customers wish to obtain optimum performance from their machines and only pay when machines actually achieve it. Thanks to our innovative methodology, we’re able to provide precisely such a service to them.” Customers can contract this maintenance model for the entire Körber Technologies machine portfolio in the secondary segment.

News & Stories - 08/26/2022

Performance based payment

Top performance as permanent status

To ensure rapid success on a lasting basis, Körber Technologies first calculates all relevant production KPIs with the customer – from output and overall equipment effectiveness (OEE) through to waste and mean time between failures (MTBF). In the next step, the achievable targets are defined for all values and the required preparations are made. “We can start after about three weeks and immediately achieve measurable and simultaneous improvements to all production KPIs,” explains Vikki Lu, Asia Strategic Officer at Körber Technologies. “It’s then a case of sustaining these new optimum levels for all values for the long term.”

lWith KPI driven Maintenance, customers pay for results, not for resources.r

Vikki Lu, Asia Strategic Officer Körber Technologies

All-inclusive, carefree packages

This is precisely what Körber Technologies is responsible for during ongoing operations on site. Körber Technologies logs all relevant KPIs on a continuous basis, evaluating them in real time. Körber Technologies has the required wear parts available, monitors the machine’s settings and carries out all necessary maintenance pit stops so that it can respond to deviations in the machine’s performance target.

Conventional maintenance intervals with long machine downtimes are thus now a thing of the past. “This approach ensures that the all-too-familiar effect of a continuous drop in performance after achieving optimum levels is kept at bay. We thus offer customers numerous advantages,” states Castro. “Alongside rapid and simultaneous improvement in performance with regard to all relevant criteria, customers also benefit from the time-tested methodology that Körber Technologies Advanced Services brings to the table.” Manufacturers thus not only save on their own human resources but also broaden their expertise due to the constant knowledge transfer.

Cost advantage thanks to performance based payment

Vikki Lu believes that the cost advantage is highly attractive for customers, not only in terms of the savings potential achieved through standardisation: “Manufacturers only pay for what they want and get. More specifically, this means that customers pay less if a machine remains below a targeted optimum level. If performance falls below a red line, they don’t pay a thing.”

Share this article