What are the advantages of cylindrical pre-rollers over tapered connections?

Unlike the predominantly known cone joints, cylindrical pre-rolls provide a standardized smoking experience, improve production efficiency, ensure consistent product quality, and promote regulatory compliance in the hemp industry.

To illustrate the main advantages of cylindrical joints compared to the usual cone joints, we have listed the strongest points of straight pre-rolls:

Reducing production costs: conquering the pre-rolling industry with competitive prices

One of the outstanding advantages of cylindrical pre-rolls compared to cones is their remarkable potential to reduce production costs. The cylindrical format offers a more economical and efficient production process that requires fewer materials and leaner manufacturing processes. Unlike cones, which require additional materials and complicated forming processes, cylindrical pre-rolls are easier to manufacture, resulting in significantly lower material and labor costs.

With production costs as low as $0.01 per unit compared to cones, which cost about $0.05 per unit, the cost efficiency of cylindrical compounds is proving to be a key advantage for pre-roll manufacturers. By taking advantage of this cost reduction potential, manufacturers can not only increase profitability, but also gain a competitive advantage in the dynamic and expanding pre-roll market - all while providing high-quality products for discerning consumers."

Scalable production: meeting the demands of a growing market

Cylindrical pre-rolls offer pre-roll manufacturers the advantage of scalable production and enable them to efficiently meet the demands of a rapidly growing market. With state-of-the-art machines such as the Nano-H, manufacturers of stock rolls can significantly increase their production capacities.

With our Nano-H machine capable of producing up to 5,000 pre-rolls per minute, manufacturers can efficiently fulfill larger orders and expand their customer base. This scalability not only increases operational efficiency, but also enables manufacturers to take advantage of opportunities created by increasing demand in the pre-roll industry.

Improved longevity: less susceptible to damage during packaging and transport

Another significant advantage of cylindrical pre-rolls is their superior durability compared to conical pre-rolls. The cylindrical shape of the tube joints provides greater resistance to damage during packaging and transportation. This feature ensures that pre-rolls arrive in perfect condition, reducing product loss and increasing customer satisfaction.

Versatile packaging: simplicity and cost efficiency

Tubular pre-rolls offer pre-roll manufacturers a packaging solution that is both easier and less expensive to implement compared to cone pre-rolls. The cylindrical shape lends itself well to efficient packaging and reduces the risk of product breakage. In addition, the packaging process can be better automated, saving manufacturers time and labor costs.

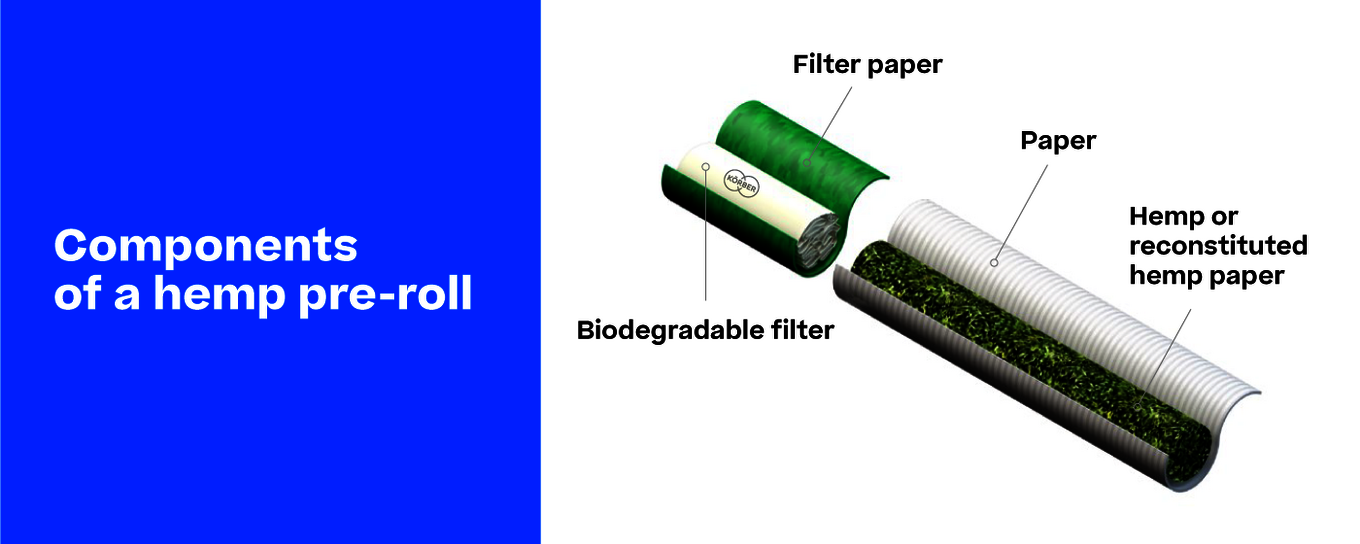

Biodegradable filters: commitment to sustainability

Körber stands for innovation and their for also for sustainable production processes, moreover environmental concerns become increasingly important in the cannabis industry too, pre-roll manufacturers are actively promoting sustainability. Cylindrical pre-rolls offer these manufacturers an excellent opportunity to prioritize environmental awareness in their production processes. By incorporating biodegradable filters into the production of pre-rolls, manufacturers are contributing to a greener future while meeting the demands of environmentally conscious consumers.

More than that the use of tubing connections allows for the seamless integration of these biodegradable filters, providing a sustainable smoking experience that is consistent with environmental values. This commitment to sustainability positions pre-roll manufacturers at the forefront of eco-friendly practices in the cannabis industry.

Improved product customization: meeting consumer needs with multiple filter options

The beauty of cylindrical pre-rolls lies in their unparalleled flexibility, allowing manufacturers to adapt their products to different consumer preferences. Whether it's a squeeze filter, a biodegradable filter, a regular acetate filter, or even flavored filters, our Cantos and Nano-H machines can seamlessly incorporate any type of filter desired. Switching between different filter materials is effortless and requires no set-up time.

For those who opt for the more compact TFM (Tube Filling Machine), there is also good news, as a wide range of prefabricated tubes with different paper and filter combinations is available. There is also the Nano-T Tube Maker from Körber Technologies, which can produce up to 8,000 filter tubes per minute and can be converted from 15 mm to 25 mm filters in less than four hours.

This versatility allows manufacturers to serve an ever-evolving market and ensure that their cylindrical pre-rolls resonate with discerning consumers seeking customized experiences.

Popularity and better smoking experience: familiarity and airflow

Cylindrical pre-rolls offer a smoking experience that is familiar to tobacco users. The shape and airflow of tube pre-rolls closely resemble traditional tobacco cigarettes, giving consumers a sense of familiarity and comfort. This familiarity, combined with the better smoking experience that cigarette-style pre-rolls offer, makes them an attractive choice for consumers, further increasing their popularity in the market.