News & Stories - 07/23/2024

Energy conservation thanks to induction heating

The global shift towards more sustainable household solutions is highlighted by the changeover from gas hobs to induction cookers, marking a notable advancement.

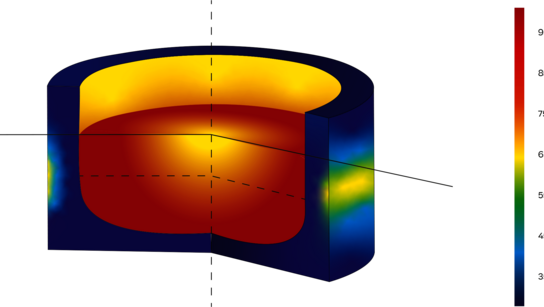

Our experts within the Körber Business Area Technologies see this transformation as the basis for innovations that assist customers in their transition from fossil fuels to electricity: as part of an R&D project, they have devised a concept for heated tanks in the Primary sector, based on induction technology, to replace conventional heating systems with steam.

Greater heating efficiency, fewer CO2 emissions

“Using this idea as a starting point, we have developed an initial prototype as a proof-of-concept, enabling the use of renewable energy sources and aligning with our sustainability goals,” reports Marco Morandin, Head of Sales Primary in the Körber Business Area Technologies. “What’s more, the solution comes with additional benefits, such as a significant reduction in carbon emissions, enhanced heating efficiency compared to steam and more precise temperature control thanks to the option of accurate energy supply modulation.”

Moreover, the innovative tanks can be installed more flexibly and quickly, as no complex steam distribution system is required. This reduces maintenance costs for customers and improves workplace safety.

Enormous effect

If we take a look at the figures, we can see the effect that the new technology can achieve: the emissions produced by global tobacco production amount to six million tons of carbon equivalent (CO2e) per year. With the induction-heated tanks, up to 1.4 kg of carbon equivalent can be saved per ton of tobacco. A typical Primary machine has a capacity of 5,000 kg/h and uses at least two tanks. “That means a reduction potential of 7.24 tons of carbon equivalent per year,” states Morandin. “If you consider that we manufacture between 15 and 20 tanks every year, we could reduce our Scope 3 emissions by 1,000–1,400 tons of carbon equivalent as a result.”

Share this article